|

|

Any questions?

|

Focus on your product

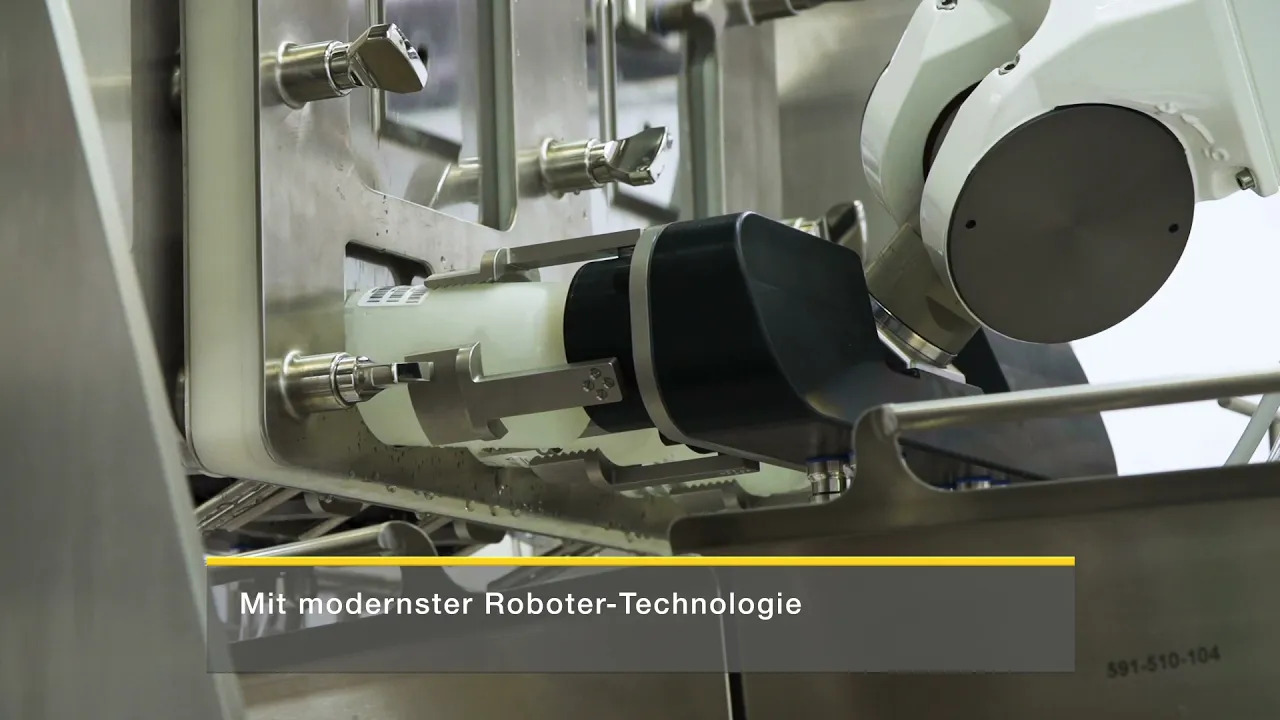

Individually designed, planned and manufactured – with state-of-the-art technology

HOF systems – state-of-the-art technologies for practical applications

Equipment and systems from HOF are designed and implemented precisely to your individual requirements. We use state-of-the-art technologies in the equipment and systems to achieve excellent results.

HOF systems are often highly innovative and many new developments have been patented. HOF products can be characterized in three words which are important for pharmaceuticals and biotechnology: future-proof, powerful and practical.

HOF is known for innovative products which are developed precisely to the customers’ requirements using the latest technologies and a lot of know-how. As in all our systems, our service also proves that HOF is the specialist for individual solutions. Our systems a glance:

- Laboratory systems (GLP)

- Vial production systems (GMP)

- Bulk production systems (GMP)

- Loading and unloading systems (GMP)

- Freezing and thawing equipment (GMP)

Freeze drying systems

HOF freeze drying systems – customised, reliable and easy to operate

HOF freeze drying systems are tailored individually and precisely to the task at hand and to the specific production requirements. For systems which are required for research or for product and process development, we guarantee that the respective process parameters are fully transferable to the production systems. That ensures reliable production!

And: Each system is ideally adapted to the structural environment on site.

Keeping an overview with HOF software

The specially developed software from HOF makes the process control of HOF systems particularly user-friendly. All functions are always visible at a glance and any irregularities are identified immediately.

An optional remote control function provides reliability in production, because the cause is analysed precisely straight away in case of a malfunction.

Our own products also include a visualisation system for creating product-specific temperature profiles, system visualisations and batch-based documentation of processes.

Vial and bulk systems – variety in top quality

Freeze drying systems

HOF is the specialist for individual solutions. That is why freeze drying systems are tailored individually and precisely to the task at hand and to the specific production requirements. And: This allows us to ideally adapt each system to the structural conditions on site. In this area, HOF offers a wider range of freeze drying systems, with regard to system size, model variants and optional equipment. The portfolio ranges from small pilot systems with a footprint from 2.5 m2 to systems with a footprint of 75 m2.

The following equipment variants are available:

- Vertical design

- Horizontal design

- Modular technical units which can be installed according to the building situation

- Door concepts:

- single door

- double doors (facing as a reach-through system)

- slot door especially for automatic loading and unloading systems

- slot door integrated into swivel doors

- The systems can be equipped with different cleaning and sterilizing units for aseptic processing areas and with systems for decontamination of the system periphery.

- System design for drying products with organic solvents

- Systems for process monitoring and process analysis

- Refrigeration systems:

- two-stage refrigeration sets with synthetic refrigerants

- cascade refrigeration sets with natural refrigerants

- LN2 refrigeration via heat exchangers for the installation areas and the ice condenser

- LN2 refrigeration as direct evaporation for the ice condenser

For the vacuum systems, HOF offers different variants for different requirements:

- Oil sealed rotary vane pumps with or without Roots-type blower

- Glandless pumps with Roots-type blower

- Screw compressor with or with or without Roots-type blower

- Upstream or downstream exhaust gas filtration

As a specialist for individual solutions, HOF can also supply systems for different requirements in bulk production:

- Systems with fixed shelves for loading with trays

- Systems with hydraulically height-adjustable shelves for easer tray handling

- Systems with tilting shelves for cascade filling, with the shelves designed as product pans The CIP/SIP process can be used here to reload the system with products without opening the chamber door.

Different systems are available for unloading. These are selected according to individual requirements. The same options are available for vial and bulk production systems.

Laboratory systems – optimum system technology, optimum equipment

The customised laboratory systems from HOF with very high quality are used in many renowned companies and scientific facilities for research purposes and for product and process development.

Highly efficient product results

HOF offers the modern systems in compact or split design with a footprint of 0.2 to approx. 2.5 m2. Control, visualisation and technical operation correspond to that of a production system. Transferring the determined process parameters to a production system is made easier and forms the foundation for reliable production. Each HOF laboratory systems consists of a fully functioning basic unit. Individual equipment variants for customised solutions are also available, providing the required flexibility for the task at hand.

Technical data

- Total footprint: 0,22 m2 to 2,5 m2

- Number of shelf sets: 3+1 to 7+1

- Dimensions of shelf sets (mm): 250/300; 420/470; 600/600

- Hydraulic adjustment of shelves

- Operating voltage: 400 V/50 Hz

- Cooling from +20° C to -50° C ≤ 40min

- Heating from -40° C to +20° C ≤ 60 min

- Temperature range from -55° C to +80° C (optionally down to -60° C)

- Evacuation time from 1000 mbar to 0,1 mbar ≤ 20 min

- End vacuum: 5 µbar

- Leak rate: < 0,01 mbar*l/s

- Ice capacity: 4 - 40 kg

- Temperature minimum condenser: ≤ -70° C (optionally ≤ -75° C)

- Control: Siemens SPS S7-300

- User interface: HOF Freeze Viewer Professional

Controlled nucleation is a hot topic in the field of pharmaceuticals.

With the objective of offering users another tool for increasing the quality of the pharmaceutical product while ensuring efficient operation of the freeze drying plants, HOF introduced the “SynchroFreeze” development several years ago.

Conditioning and freezing phase

The SynchroFreeze process is characterised by a conditioning phase, followed by cooling and vacuum-induced nucleation during the freezing process. During the conditioning phase, dissolved gases are extracted from the liquid product in a partial vacuum in order to suppress increased formation of gas bubbles and swelling of the product during the subsequent freezing steps. The liquid, with most of the gas removed, is then cooled. At the desired freezing point, the nucleation is triggered with a further pressure reduction in the lower millibar range (figure 1).

All a question of the product

SynchroFreeze was examined by different development teams and application-related adaptations to the freezing phase have already been described in initial publications [1].

The conditioning periods differ depending on the product, liquid level and temperature. In addition to this, the selected freezing point and subsequent pressure adaptations offer further optimisation potential even for difficult products.

In many applications, the shelf temperature is used to initially achieve targeted undercooling while reducing the pressure level in the freeze drying chamber. Once these steps have been completed, the product is liquid and at the desired undercooling level.

Optimised product structure

Further fast pressure reduction ensures uniform freezing of the vials. The pressure reduction causes the solvents on the surface of the liquid to evaporate with localised cooling, i.e. it triggers a freezing/crystallisation process that progresses from the surface downwards. Adapting the chamber pressure therefore enables a fast and very efficient temperature change on the surface of the product.

In many cases, the targeted use of SynchroFreeze makes it possible to optimise the product structure (figures 2 and 3) and significantly shorten the drying periods.

The larger structure of the lyophilisate facilitates the penetration of solvents and can therefore have a positive influence on the reconstitution behaviour.

The product-specific test results confirm the high expectations for the SynchroFreeze technology, which requires only limited modifications even for implementation on existing plants.

Quellennachweis: [1] Allmendinger, A., et al. (2016). Controlled nucleation during freeze drying using vacuum-induced surface freezing. data base no. 633018, http://www.researchdisclosure.com

HOF SynchroFreeze – for optimised freeze drying processes

- Synchronises the freezing process in the individual vials or product containers

- Conditions the product structure

- Increases product homogeneity

- Reduces the required drying periods

- Increases performance and reduces energy consumption

Freeze-Thaw Units

Freeze-Thaw Units – precise processes and own software

Adjustable freezing speed and full control over the freezing process are among the top specifications for freezing systems from HOF. The total fill quantity is frozen evenly and independent of the bag size.

Each product bag has the same freezing conditions and, at the end, the same shape. This allows bar codes to be machine-read on the flat surface, for example of a plasma bag. The reliable documentation of temperature and time are a matter of course.

Freezing systems from HOF are energy-saving with indirect refrigeration and use no energy when idle. Large doors ensure fast loading and unloading. The interior of the devices are made of stainless steel and can be cleaned easily.

HOF FTU Plasma: Freeze-Thaw Units for blood transfusion services

Adjustable freezing speed and full control over the freezing process are among the top specifications for freezing systems from HOF.

The total fill quantity is frozen evenly and independent of the bag size.

Each product bag has the same freezing conditions and, at the end, the same shape. This makes it possible for bar codes to be machine-read on the flat surface, for example of a plasma bag. Reliable temperature and time documentation is a matter of course.

Adjustable freezing with full control and proprietary software

Absolutely reliable freezing and thawing

HOF‘s Freeze-Thaw Units guarantee quality-compliant storage of blood plasma because the product bags are frozen within 45 minutes to at least -30 °C at the bag’s core. At the same time, up to 120 bags with a capacity of 400 ml can be processed. The frozen blood plasma can also be safely thawed again.

Custom requirements – individual plant sizes

Because our customers have different product capacities, there are two model types available: On the one hand, systems for processing up to 60 of the 400 ml bags are manufactured and, on the other hand, systems for up to 120 of these bags.

For individual adaptation Plants are divided into two different types. The compact design accommodates all process-relevant components within the device. On the other hand, there is the possibility of split-construction to lower the sound pressure level directly on the device. Here, the refrigeration components outside the unit are mounted on a separate machine frame.

Advantage: uniform heights of bag systems

The integrated pneumatic adjusting plate system compresses the product bags for the freezing process, so that all processed product bags have the same height after freezing.

The product bags also have flat surfaces on both sides: Barcodes can be machine-read and storage is greatly simplified.

Transparent documentation

The HOF Freeze Viewer Professional software developed by HOF is available for the documentation of processrelevant data. This software, which is configured for blood transfusion services, collects data such as bar codes, process reports and temperature history and either prints them out in the form of a process report or electronically transfers them to a higher-level system.

More than just hardware and software

The device design for blood transfusion services is based on HOF’s state-of-the-art technology. Apart from production, we also offer, as part of the scope of supply, special packaging, transport and handling support, as well as annual service and maintenance units.

HOF FTU Pharma: Freeze-Thaw Units for the pharmaceutical industry and biotechnology

Adjustable freezing speed and full control over the freezing process are among the top specifi cations for freezing systems from HOF.

The total fi ll quantity is frozen evenly and independent of the bag size.

Each product bag has the same freezing conditions and, at the end, the same shape. This allows bar codes to be machine-read on the fl at surface, for example of a plasma bag. Reliable temperature and time documentation is a matter of course.

Adjustable freezing with full control and proprietary software

Safe control of all parameters

Reliable process control is indispensable when freezing and thawing pharmaceutical and biotechnological products. The same applies to the adjustable freezing and thawing speed. Here, with the individual Freeze Thaw Units (FTUs), HOF meets all the requirements of professional users from the industry. The FTUs are each developed and manufactured according to customer-specifi c requirements. Products that have to be fed into bag systems can be transported into the plant either manually or by means of a semi-automatic loading aid developed by HOF.

Custom requirements – individual plant sizes

Two types are offered in order to respond fl exibly to on-site installation possibilities. The compact design accommodates all process-relevant and electrotechnical components inside the device.

On the other hand, there is the possibility of split-construction to lower the sound pressure level directly on the device. Here, the refrigeration components outside the unit are mounted on a separate machine frame.

Reliable cooling, reliable heating

Product tempering takes place within the FTU via a plate system. The control panels are designed to freeze the entire load evenly and regardless of bag size.

For temperature control, silicone oil is cooled with a separate cooling system or heated with the built-in electric heater. The integrated refrigeration system’s design is specified according to customer requirements. Optionally, a R452A type hydrofluorocarbon compressor system, a natural refrigerant compressor system (ethane/propene), or a liquid nitrogen system are available.

Included in delivery: „HOF Freeze Viewer Professional“

The FTUs are equipped with a visualization system for process control, the „HOF Freeze Viewer Professional“. This system complies with FDA requirements according to 21 CFR Part 11. With this software, specially developed by HOF, all process-relevant data, such as batch reports and temperature profiles can be printed out in the form of a process report or sent to a superordinate system. Customers can create respective recipes for the individual products individually.

Service is one of them

HOF’s FTUs always comply with state-of-the-art technology and meet high safety standards. Apart from production, HOF stands for comprehensive project support. At the same time, the entire project - from plant planning and production at HOF to commissioning - is entirely managed on-site by a project team. HOF is also available during transport and during introduction of training courses and the annual service and maintenance units.

HOF refrigeration

Pioneering alternatives to conventional compression refrigeration

HOF has a long-standing commitment to the issues of environmental protection, climate protection and greenhouse gases. We consequently offer our plants based on

conventional refrigeration technology as well as a whole range of refrigeration technologies that are based on the use of natural refrigerants. Instead of refrigerants with a high impact on the climate, such as R404A/R507A, these plants use hydrocarbons (ethane/propene), liquid nitrogen or – as in the case of our innovative HOF CryoBlizzard cold air machine – air as a refrigerant.

You can find more detailed information in our brochure:

Innovative refrigeration technologies

Pioneering alternatives to conventional compression refrigeration

For questions please contact Oliver Fleischer available - Department for Refrigeration Technology Development

and Service Management

Phone + 49 6462 9169-0 - fleischero(at)hof-sonderanlagen.de

The new innovative technology: HOF CryoBlizzard central refrigeration

Using air for refrigeration offers multiple advantages. For one, air is available everywhere, can be used safely and – with a GWP of 0 – does not promote climate change in any way. In addition to this, temperatures below -80 °C can easily be achieved with cold air machines such as the HOF CryoBlizzard. Legal regulations regarding the F-Gas Regulation consequently do not apply.

Ambient air as a natural refrigerant

This approach is at the core of the new and innovative HOF CryoBlizzard for refrigeration. This cold air machine allows low temperatures to be generated at a very low operating pressure using the cold air process with heat recovery. The HOF CryoBlizzard as a closed cold air machine is speed controlled and can therefore be run under partial load very efficiently.

Cooling is provided by a primary tank from which several consuming units can draw cryogenic oil. The thermal oil tank allows a high refrigeration demand to be satisfied with the relatively low refrigeration capacity of the cold air machines. And even temperatures below -80 °C can easily be achieved with the innovative and forward-looking refrigeration technology of the HOF CryoBlizzard.

A technology sets new standards

As an innovative market leader, HOF has always been thinking and acting with foresight when it comes to customer requirements. This is also true for the development of the new process of the HOF CryoBlizzard together with project partner Mirai Intex (mirai-intex.com).

A freeze drying plant from 1998 was retrofitted for this purpose. The plant is a freeze dryer with a batch capacity of 40 kg for insulin production. Before the retrofit, refrigeration was achieved with two refrigeration sets, each with 12 kg of the R404A (GWP 3922) refrigerant. The process plant was controlled by a Siemens S5 controller.

High capacities with homogeneous temperature distribution

The retrofitting converted the plant to the new HOF-CryoBlizzard refrigeration process and to the current S7-1500 controller. The new refrigeration process consists of redundant cold air machines which are switched to a central primary tank in a modular system.

The primary tank supplies the consuming units such as adjusting shelves, ice condenser or blast freezer directly with the refrigerant medium and can therefore generate large capacities with homogeneous temperature distribution within a very short time. The primary tank means that cooling water and power consumption remain constant and that no load peaks occur in the supply.

Air as a refrigerant – free and always available

The cold air machines are chillers which operate with air as a refrigerant using the Brayton cycle. The maximum overpressure in the machines is 3 bar and can be compared to that in a bicycle tyre. These machines are therefore especially safe and environmentally friendly. No special requirements result from this with regard to the machine room, employee training and recurrent testing. In addition to this, air as a refrigerant is free and always available, has a GWP of 0 and is therefore not affected by any regulations.

The HOF CryoBlizzard turbo compressor – oil-free and virtually wear-free

The refrigeration circuit is driven by an oil-free turbo compressor-expander unit with air bearings which runs with up to 88,000 rpm with virtually no wear. The refrigeration medium is cooled in the primary tank, in a heat exchanger integrated into the chiller.

The turbo compressor aspirates and compresses the air heated in this way. The energy in the gas chiller is then transferred to the cooling water. In an internal heat exchanger – the recuperator – the air is strongly cooled down and then relaxed for effective use in the expander. The work is returned to the compression.

The energy is absorbed through heating of the air in the cold medium/heat exchanger. After the air in the recuperator has come back up to temperature, it is aspirated by the compressor and the cycle starts again.

Based on this technology, the cold air machine can cover temperatures down to around -110 °C, so that the -80 °C often required in the condenser can be achieved easily.

HOF CryoProPhase – Air Purification using air as refrigerant

The processes in many industry sectors generate pollutant emissions in the exhaust gas flow, which have to be processed before being discharged into the environment.

With HOF CryoProPhase, multiple exhaust gas flows can be cleaned with a climate-friendly and future-proof technology and the pollutants can be separated effectively and completely.

This process is based on the cold air machine, which supplies multiple exhaust gas sections through a silicone oil circuit, separating the pollutants within shell and tube heat exchangers. The very cold exhaust gas flow is then used for energy recovery by means of an inner heat exchanger, allowing a large part of the pollutants to be condensed already in the exhaust gas flow and reducing the required cold input.

Based on the processes integrated into the overall procedure, not only can the limits of the German TA-Luft regulation be met, but a large part of the emissions can be fully recycled and returned into the original process. In addition to complying with the limits, this also increases the economic efficiency for the owner significantly.

Clean and environmentally friendly solution

The HOF CryoProPhase process for air purification using air as refrigerant, is thus a clean and efficient alternative to meet the highest environmental requirements.

Retrofitting existing plants or implementing new plants with the HOF CryoBlizzard

The modular design allows the capacity of the HOF-CryoBlizzard to be scaled up or down, allowing it to be adapted to anything from a laboratory freeze dryer or a production plant to a central cooling system for complete factories.

Existing plants can be retrofitted and new plants can be implemented with the HOF-CryoBlizzard. HOF has developed a future-proof solution for freeze drying and blast freezing which is not only safe for employees and the environment, but also sets new standards with regard to the quality and availability of the application.

Benefits at a glance:

- Natural refrigerant (GWP 0)

- Uses ambient air

- “Scale up” using central cooling

- Future-proof and not affected by regulations

- Low maintenance effort

- High temperature flexibility

- Low noise emissions

- Nearly no requirements for machine room installation (pressure analysis/refrigerant)

- Very low training required and good safety aspect for employees and site

The energy balance is also impressive

The energy balance of the retrofit was compared to the existing sister plant. This reflects the exact 100 % comparison. A specialised external engineering office was commissioned to examine the potential of this technology: a 5 to 10 % saving over the comparable process in the sister plant.

Another reference is the HOF CryoBlizzard and the associated data that is used as a scientific basis for applying for future cold air plants. For example: HOF participated in the application for the funding eligibility of cold air plants with the German Federal Office for Economic Affairs and Export Control (BAFA).

Conventional refrigeration technology - small space requirements and low investment costs

Refrigerants such as R452A, R404A, R410A or R507A are used in conventional refrigeration technology, which we offer with two-stage compressors for refrigeration in the freeze drying process if requested by the customer. As known and well-tried refrigerants, these have the advantage of being non-flammable and non-toxic. They also require little space and low investment costs. With respect to the F-Gas Regulation, however, some legal regulations have to be taken into account.

The objective: combining proven technology and the F-Gas Regulations

The compression refrigeration cycle used to be the most commonly used refrigeration cycle. This refrigeration process is based on boiling and condensing refrigerants. These will have to be replaced or reduced in the future to meet the targets of the European F-Gas Regulation.

This entails a gradual reduction of the quantities of hydrofluorocarbons which can be placed on the market in the EU. This will result in a shortage of the available conventional refrigerants such as R404A, for which HOF has been preparing with alternative refrigerants and technologies for many years. While these refrigerants with a GWP > 2500 may still be used in the low-temperature sector (product application below -50 °C) until the year 2030, there are already supply bottlenecks paired with strongly rising prices today. After setting up an in-house test bench in 2015, HOF was the first manufacturer to establish the LOW-GWP alternative R452A (GWP 2140) in the field of freeze drying/blast freezing.

This refrigerant is ideal as a drop-in for existing plants and as a proven refrigerant for new plants. The high-pressure refrigerant R410A (GWP 2088) is another alternative for conversions or new plants. This allows us to offer all customers options for complying with the F-Gas Regulation (GWP < 2500).

Two-stage compression chiller

In contrast to air refrigeration, steam refrigeration is the idealised CARNOT process. In practical application, this two-stage compression refrigeration cycle is a sophisticated technical design. Firstly, the technology depends on the material properties of the refrigerants and on the properties of the components. Secondly, it is important to find an ideal process solution for oil transport and the vacuum operation required by the design.

In two-stage compression chillers/displacement chillers, the entire pressure ratio is divided between two compressors or, by design, in a two-stage chiller. The compressor in the first stage compresses the refrigerant from the lowest pressure level to a medium pressure. With the booster placement, the second compressor compresses the refrigerant from the medium pressure to the high pressure.

Benefits of conventional compression chillers:

- No special requirements for the material

- Proven, tested and optimised technology since 1988

- Refrigerant in safety group A1

- Space requirement

Liquid nitrogen - a natural refrigerant

Our plants with liquid nitrogen as a refrigerant offer immediate cooling performance, because the -196 °C cold nitrogen is supplied directly from nitrogen tanks installed outdoors. In addition to this, these plants offer easy commissioning and a future-proof design because they are not affected by new legal regulations. They also impress with low maintenance costs while offering a high level of temperature flexibility.

A simple process with a natural substance from the atmosphere

The advantages of the HOF freeze drying process with liquid nitrogen as a refrigerant are based on the refrigerant itself: Nitrogen is a naturally occurring component of the atmosphere. Delivered by the nitrogen supplier and stored in outdoor tanks, the refrigeration capacity is available immediately and without restrictions. A factory nitrogen network can be used as an alternative, so that no additional operating costs are incurred with regard to the infrastructure. The high refrigeration capacity is achieved by vaporising the nitrogen. The used nitrogen can then be utilised for other processes such as pre-chilling, or safely discharged into the atmosphere.

Low failure frequency and low maintenance

In addition to the benefits provided by the nitrogen, the HOF plants offer additional advantages: The systems have a very simple design and only few moving parts, because the nitrogen is conveyed in the system by means of the pressure in the tank. This ensures a high level of durability and low maintenance effort.

Proven technology – the details

When nitrogen is used for refrigeration, HOF replaces the chillers with cryogenic heat exchangers. These can be a direct evaporative condenser, developed by HOF, or supplied by a secondary cycle with a heat exchanger.

As for all refrigeration types, even temperature distribution for the adjusting shelves is, of course ensured. Oil-controlled as well as direct evaporative condensers can therefore be adapted to any customer requirements.

Benefits of freeze drying with liquid nitrogen:

- Natural refrigerant (GWP 0)

- Simple process

- Proven since 1994

- Future-proof and not affected by regulations

- Low noise emissions

- Low maintenance costs

Hydrocarbon - future-proof and not affected by regulations

Our two-stage CAR6 cascade system allows us to achieve low temperatures with natural refrigerants. The refrigerants used are the hydrocarbons ethane and propene, which allow a very high level of efficiency to be achieved with maximum flexibility. The cascade systems ensure safe operation of a plant which is also future-proof.

Compression chiller as a cascade

The cascade is another variation of the classic compression refrigeration cycle. The basic principle links several separate refrigeration systems with different refrigerants. For natural refrigerants, we use a two-stage cascade.

The refrigerant ethane (R170) used in the first stage is available for any low temperature application. In the second stage, we use the natural refrigerant propene (R2170). In addition to liquefying the ethane (R170), this stage also supplies a control stage for the adjusting-shelf cycle.

Successful launch of HOF-CAR6 in 2007

The objective of the European F-Gas Regulation is to substantially reduce the use of hydrofluorocarbons. In fact, HOF has been working on new processes with natural refrigerants for many years.

A cascade system which uses ethane and propane was consequently established in the market by us as far back as 2007. The cascade system consists of two separate cycles which form an individual module. To achieve redundancies or capacity increases, additional modules can be combined flexibly based on customer requirements.

Excellent safety based on excellent experience

Each individual module is placed in a special housing. This containment generates a hermetically sealed unit in the event of a fault. If a fault occurs, a fan removes the refrigerant atmosphere in the affected containment.

The individual module can also be disconnected from the power supply. The capacity exchange takes place in each individual module for each consuming unit. This means that the condenser as well as the adjusting shelves are implemented as oil-controlled consuming units.

This special redundant design generates the product safety in the event of a fault. There is no substitute for experience – and more than 80 years of individual modules implemented by HOF are proof of the know-how and pioneering spirit.

Benefits of freeze drying with a natural refrigerant:

- Very low GWP ≤ 6

- High efficiency

- Experience since 2007

- Future-proof and not affected by regulations

- Modular system

- Reliability

Loading and unloading systems

HOF Loading and unloading systems - safe and patented

The safe, optimum and integrated transport of pharmaceutical products and primary packing is the core property of the loading and unloading systems from HOF. The large number of models for loading freeze dryers ranges from models for technical centres to production sizes. And: It allows individual adaptation to any layout. The new design was specifically adapted to customer-specific requirements. High performance and reliability are the crucial factors here. The range covers manual, semi-automatic and fully automatic systems. Special packaging materials such as 2-chamber vials or 2‑chamber syringes can be transported with ease. We hold patents worldwide for these technologies.

Versatile and individual

The loading and unloading systems are installed and tested at our own production facility together with freeze dryers or in front of a suitable dummy frame. The clear advantage is the reduced installation and test period at the customer site. Existing freeze dryers can be retrofitted with the innovative loading and unloading systems from HOF to meet future requirements. Depending on the requirements, loading and unloading systems can be designed for insulator or RABS technology.

Bulk systems

Automatic

- Robot with filling lance

- Robot with suction device

- Product separator

Semi-automatic

- Filling trolley with dosing system

- Filling trolley without dosing system

Manual

- Lances for filling process

- Lances to the filling process

- Product separator

Vial systems

Frames/magazines

- Magazine filling

- Manual transfer trolleys to freeze dryer

- Semi-automatic loading and unloading

- Automatic loading and unloading

Frameless row by row

- Loading and unloading row by row

- Loading row by row

- Unloading row by row

- Unloading multi-segments

- Batch loading for trolley systems

Frameless by shelf

- Loading and unloading trolley system

- Loading trolley system

- Unloading trolley systems

HOF VTS: Vial transfer system

S – safe

M – modular

A – automated

R – reliable

T – time-efficient

The demand for high-quality loading and unloading systems for freeze-drying systems in the pharmaceutical and biotechnological industry is increasing and, with it, the technological requirements. HOF fulfils this need - with the right innovative answers and the expansion of reliable and high-quality production.

Therefore, new developments have been continuously implemented in the field of loading and unloading systems in the past. The new HOF VTS meets the highest customer demands and is a good example of HOF’s knowledge, creativity and innovative power.

HOF VTS – pure Innovation

Reliable, functional and easy cleaning processes

Reliability and fast detection of individual objects all the way to hygienic design are crucial for HOF plant sensor technology. The same with the HOF VTS.

The latest sensor technology made of stainless steel with adequate shape requires high functionality and guarantees optimal cleaning and sterilization results.

Production reliability is additionally increased by not having to readjust the positions during possible sensor replacement.

All machine parts in the classified area have been tested with regard to the hygienic design so that the largest possible radii, selection of materials and easy disassembly for the cleaning process have a decisive influence on the results.

Shorter changeover times

Changeover times with varying vial sizes will be significantly reduced in the future with the HOF VTS series through a simplified functional design of the format parts. The same with the new HOF VTS.

An exchange of format parts in a cRABS or an insulator is simplified even by glove intervention. Format parts with bottleneck guides are used at certain points to increase production safety.

All format parts are designed to avoid confusion.

Flexible control technology and intuitive user guidance

In the future, control technology of the loading and unloading systems will focus on the new possibilities offered by Siemens as part of the TIA Portal (Totally Integrated Automation Portal).

The user software’s user interface has been oriented towards the future and has been specially designed for application in the clean room. This increases flexibility and guarantees state-of-the-art, needs-based technical solutions.

Intuitive operator guidance via touchscreen, permanently assigned function keys or a combination of both, new control panels used by HOF, now standardized, provide an optimal solution for users. Displays with a wide viewing angle ensure an optimal overview of all plant conditions.

The HOF VTS sets new standards for design, technology and functionality

Construction:

- Format widths up to 1520mm

- Fixed side guides on the individual positioning plates, transfer plane and buffer surface

- All stainless steel components in contact with the packing device are provided with an FDA-compliant coating to minimize friction.

- HOF VTS can be used both in the RABS and in the isolator

- Mechanical connection between the individual panels and the transfer level to ensure a clean transition between components

- Unloading unit inside the freeze dryer (ejection unit’s CIP and SIP, no additional space required in the equipment room behind the freeze dryer)

- Bellows optionally made of PTFE or stainless steel

- Format-independent horizontal vial ejection

- Format-independent horizontal vial recognition

- Small format parts for easy handling

- Short changeover times through the use of universal format parts

- Easy sensor replacement without reorientation

- All format parts can be mounted or adjusted without tools

Process:

- Row-by-row loading after single-lane feeding of vials by the upstream machines

- May be discharged as single row or multi-row

- Vial neck guides at critical points to improve vial stability at high levels of performance

- Automatically-swiveling hexagonal stopper for transporting vials

- Correction value entry for hexagonal stoppers for vial tolerances

- Freely adjustable system output of 20-100%

- Verification of row length before transferring on the buffer surface

Cleaning:

- Band body as open construction for improved H2O2 decontamination is possible

- Hygienic design sensors with resistance to H2O2 and all common cleaning agents

- HOF WIP cleaning system (wash-in-place), for example, toxic applications

- Material selection is based on common cleaning agents for highest possible resistance

Control:

- All drives are provided as servomotors with integrated absolute encoders

- Operation of the loading/unloading system and freeze dryer through a control panel

- Input table for precise positioning and identification of sample vials

Operating modes: Production, Cleaning, Service, Sensor test

PAT technolgy:

- Automatic exchange of normal plugs against prepared plugs with wireless temperature sensors at a freely selectable position on the positioning plate

- Automatic removal of vials with wireless temperature sensors before transferring vials to the crimper

- Detection of prepared vials via camera system

- Fully automated stopper handling via robot system (clean room-suitable, H2O2-resistant)

HOF SIRIUS robot-assisted loading and unloading system

Future-proof, powerful and practice-oriented

The requirements in the field of automatic loading and unloading of a freeze dryer are growing rapidly. Pharmaceutical products and primary packaging material must be transported safely, optimally and in an integrated way. Based on these requirements, HOF, as the professional market leader, has developed an innovative robot-assisted loading and unloading system. The HOF SIRIUS new development convinces with its innovative technological character and is a sophisticated high-tech loading and unloading system.

Very gentle product transport system

SIRUS transports vials without glass-to-glass contact from the upstream machine to the freeze dryer. In the freeze dryer, a homogeneous, hexagonal vial pack is set up and placed on the shelves of the freeze dryer, independent of vial tolerances.

By transporting the vials in format-specific nests mounted on individual electromagnetically driven movers, the possibility of fallen vials on their way from the upstream machine to the freeze dryer is eliminated.

State-of-the-art robot technology ensures a maximum flexibility in the pharmaceutical sector

A specially newly developed transport system ensures gentle product transport as well as the traceability of each individual vial during the loading process.The two 6-axis robots from Stäubli in the Stericlean version and the electromagnetic XTS-Hygienic from Beckhof ensure maximum flexibility in the pharmaceutical sector.

The system can be integrated into both a RABS and an isolator. All components meet the hygienic requirements demanded in the pharmaceutical environment and are resistant to H2O2.

Powerful loading and unloading system

Unloading of the freeze dryer is done according to the row by row principle. This means that the individual vials can also be traced back to the downstream machine. Thanks to the innovative interaction of a high-tech transport system and modern robot technology, HOF is able to meet the high requirements of aseptic loading and unloading of a freeze dryer in the smallest possible space.

Depending on the size of the freeze dryer, this system can be easily scaled up to meet our customers’ requirements. The capacity can be scaled depending on the size of the freeze dryer and the packaging material, up to 400 vials/min for loading and 400 vials/min for unloading.

SIRIUS can therefore cover the loading and unloading processes of the freeze dryer in the small-scale sector as well as in large production plants.

Technologically versatile and individual

SIRIUS is a modular system that can be adapted to any layout. It can be supplied with vials from one side and also conveys the dried product back in this direction to the downstream machine. Alternatively, the product can be transported out on the opposite side after freeze-drying. Pass-throughconveying in the case of liquid filling is also possible.

By eliminating conveyor belts, glass-to-glass contact, and the accumulation of vials on conveyor belts, SIRIUS significantly reduces particle generation.

SIRIUS is also adaptable to already known applications, such as automatic stopper placement with temperature sensors, and is a system that combines all previously known vial handling possibilities with the latest technology, increasing process reliability and reducing manual operations.

SIRIUS Long-term testing

The HOF SIRIUS system has now successfully completed long-term testing.

Process optimisations such as maximum loading and unloading speed, emergency management and the new user interface were tested successfully and will continue to be enhanced in the time to come.

Other features such as detecting and evaluating the vial package in the freeze drying plant with a camera system are currently being implemented on the prototype. Together with various manufacturers, we are narrowing down the optimum system for our customers and integrating it into the plant control to further increase process reliability.

Advantages at a glance

- Flexibility – can be adapted to all freeze-dryer sizes

- State-of-the-art robot technology

- Short set-up times

- Easy and fast cleaning

- Intuitive operational guidance

”The HOF SIRIUS new development is a technological highlight and meets all the requirements for a safe and powerful loading and unloading system.“

Contact

To contact us or if you have any questions, please contact

Take a look at the detailed product video!

Special solutions

HOF waterbath & debottling system

The innovative HOF waterbath & debottling system was developed for automated, targeted defrosting of frozen plasma bottles, allowing the remaining frozen core and the surrounding liquid to be removed easily after cutting open the bottles.

Fully automated transport

First operators load the magazine which can contain up to 16 bottles. The bottles are then moved onto the conveyor belt and into the 4 tracks of the water bath.

Defrosting process of the human plasma

There, the plasma bottles move through the heated water bath while submerged. The defrosting causes a thin layer of the human plasma to thaw at the contact surface with the plastic bottles. At the end of the water bath, the plasma bottles are sprayed with hot WFI to counteract germs and particles on the bottle surface. They now surpass an air knife to remove potential remaining condensate.

Fully automated cutting station – “guillotine”

Then the plasma bottles drop into the “collection hopper”, in an upright position for the first robot ... which grabs the plasma bottles and guides them into the subsequent cutting station. From the other side, the second robot grips the plasma bottles by the base. Then the bottles are cut in half.

State-of-the-art robot technology

After cutting, both robots empty the bottles halves with the human plasma cores into the draining trays. Subsequently, the plasma slides or flows through a guiding channel into the pooling vessel.

Based on a sensoring system, the bottles are checked if they are completely empty, before the empty bottle halves are placed on a discharge rail, leading to a disposal tube.

Compact, reliable and safe

The HOF waterbath & debottling system, consisting of water bath and cutting station, is a highly innovative technological solution.

HOF systems can be described in three words: powerful, practical and future-proof.

Take a look at the detailed product video!

HOF waterbath and debottling system

The innovative HOF waterbath & debottling system was developed for automated, targeted defrosting of frozen plasma bottles, allowing the remaining frozen core and the surrounding liquid to be removed easily after cutting open the bottles.

Fully automated transport

First operators load the magazine which can contain up to 16 bottles. The bottles are then moved onto the conveyor belt and into the 4 tracks of the water bath.

Defrosting process of the human plasma

There, the plasma bottles move through the heated water bath while submerged. The defrosting causes a thin layer of the human plasma to thaw at the contact surface with the plastic bottles. At the end of the water bath, the plasma bottles are sprayed with hot WFI to counteract germs and particles on the bottle surface. They now surpass an air knife to remove potential remaining condensate.

Fully automated cutting station – “guillotine”

Then the plasma bottles drop into the “collection hopper”, in an upright position for the first robot ... which grabs the plasma bottles and guides them into the subsequent cutting station. From the other side, the second robot grips the plasma bottles by the base. Then the bottles are cut in half.

State-of-the-art robot technology

After cutting, both robots empty the bottles halves with the human plasma cores into the draining trays. Subsequently, the plasma slides or flows through a guiding channel into the pooling vessel.

Based on a sensoring system, the bottles are checked if they are completely empty, before the empty bottle halves are placed on a discharge rail, leading to a disposal tube.

Compact, reliable and safe

The HOF waterbath & debottling system, consisting of water bath and cutting station, is a highly innovative technological solution.

HOF systems can be described in three words: powerful, practical and future-proof.

Take a look at the detailed product video!

Service

Our service for you – as individual as our solutions

Only our own employees work on your system at HOF – even long after it has left our factory. HOF employees transport, install and commission your system and also qualify it. This minimises interfaces and excludes problems, saving time and costs.

24 hours service

You can always reach one of our employees in emergencies at +49 6462 9169-0. 24 hours a day, 365 days a year. Why? Simply because we know that our systems are an important part of the production process and that production reliability has to be ensured. Our emergency team from service and production know the system down to the last detail and can help immediately to keep downtimes as short as possible. The on-site warehouse with over 60,000 items ensures that the essential spare parts for all systems are always available without delay.

You can download our HOF Quick Support here.

Documents for download

At HOF you can now download the calibration certificates of the reference measuring instruments you use.

Please fill out the form, which you can request via this link Calibration Certificates. You will receive the access data immediately by mail.

Qualification – for your reliable production

We qualify your systems in a GxP-regulated environment. Our own qualification department creates the individual qualification and validation requirements for our systems. This includes:

- Performance specification

- Project and quality plan

- System description

- Risk analysis for system-specific risk scenarios

- Hardware design specification

- Software design specification

- Traceability matrix

- Calibration and SAT (site acceptance test)

- Qualification documentation for IQ and OQ

Extensive measurement equipment

The documents are created and coordinated based on a performance specification. HOF carries out the tests planned in the qualification documents. Extensive measurement equipment is available for calibration and qualification. The following are calibrated:

- Temperature

- Relative pressure

- Absolute pressure

- Vacuum Pirani and capacitive

- Conductance

- Flow rate and others

Among others, Kaye validation systems are used for the qualification in the framework of temperature distribution measurements and sterilisation validation. The validation and qualification systems are subject to continuous testing.

Qualified process development

The services provided by HOF also include qualified process development to offer you added reliability. We use our extensive modern equipment and the available laboratory systems to support you in all matters of process control. This allows us to reduce process times and optimise the quality of the dried product where possible. Equipment for resistance and temperature measurement as well as a cryo-microscope are available for detailed examination of your product.

Design and concept studies – individual and excellent integration

A sound concept is always the basis for the success of your project. As a specialist for individual solutions, we ensure the best possible integration of freeze drying equipment and systems in industry and research. Customised concept studies and plans in 2D and 3D form the basis for our joint work. In addition to the functional aspects, other important parameters are also taken into account:

- Reliability of the system

- Easy access for service and maintenance

- Safety

- Investment and availability of the systems

- System capacities

Maintenance – safety through regular checks

Regular maintenance is necessary for perfect functioning of your system. We recommend annual maintenance – necessary due to the service life of seals, for example. It is practical to carry out the annual calibration of the measurement equipment and the sensor system at the same time. After completing the maintenance and calibration work, the systems undergo documented test runs. What is important in this context: The HOF team is also available for freeze dryers from other manufacturers!

Training – successfully transfer of knowledge

For the targeted transfer of knowledge, we always offer training courses which are adapted to your company and your system. HOF training courses are designed to familiarise your employees with your individual system fundamentally and comprehensively, reducing downtimes, enabling fast and independent working and increasing productivity. To increase learning success and knowledge transfer, our employees focus on a personal teaching approach based on practical application.

LYOPOOL

LYOPOOL

The stocked HOF systems are a well-established and safe investment, due to their short-term availability and superior quality.

A broad portfolio encompassing anything from lab freeze dryer systems to production plants to freezing- and thawing machines is available in our own store for you to choose from.

Before shipping and hand-off, every system is rigorously tested by HOF. This offers safety and guarantees a long service-life. Specific requirements of your unique application can be implemented in the systems.